A double drop trailer solves a simple problem: your freight stands too tall for many common decks, but you still want to stay as close to legal height as possible. People also call it a double drop deck trailer, and many drivers group it with the larger lowboy trailer family.

The main feature is the “well” in the middle. It is lower than the front and back sections. This design helps you carry taller loads. It also gives you better ground clearance control than a regular drop deck.

Below is a practical breakdown of what it does best, what to watch for, and how to pick the right setup.

What makes a double drop different from other drop deck trailers

Most drop deck trailers have one main step down from the top deck to the lower deck. A double drop trailer adds a second drop, creating a low “well” section between the gooseneck area and the rear axles. That lower center deck gives you a lower deck height, creating more room for freight before you hit height limits.

In many common configurations, the well deck height is typically 18 to 24 inches, and the well length is typically 24 to 29 feet. Exact numbers vary by manufacturer and axle setup, but the idea stays the same: lower deck equals more legal headroom.

When should you choose a double drop trailer?

Choose a double drop trailer when you transport heavy equipment or freight. This is best when your load is tall for a step deck or standard drop deck.

A double drop trailer has a lower deck, so the load rides lower and steadier from start to finish. That lower position can improve stability, reduce stress on the machine, and give you more breathing room when you plan routes with bridges, signs, and tight clearances.

This trailer type often gives you room to haul taller loads while staying within legal height limits, depending on the deck height and the exact shape of the load. It also helps when the freight has high points, like a boom, cab, or attachment. A few inches lower on the deck can mean the difference between an easy move and a permit problem.

This makes it a great drop trailer choice for excavators, dozers, and heavy machines. These machines can be hard to load on higher decks.

Key terms that matter on a double drop deck trailer

Well (lower deck): The lowest section where the cargo sits. This section drives your usable height.

Deck height: The distance from the ground to the deck surface in the well. Many double drops sit roughly in the 18 to 24 inch range, though some setups sit even lower.

Ground clearance: A lower well helps height, but you must watch breakover angles, railroad crossings, dips, and steep driveways. A very low deck changes how you approach entrances and exits.

Removable gooseneck: Many double drops come as an RGN setup. A removable gooseneck lets you detach the front so you can drive equipment onto the deck instead of loading from the side with a crane.

Weight and legal basics you should not ignore

Even when height drives the decision, weight still decides what you can move without extra steps. In the U.S., the common interstate planning number sits at 80,000 lbs for gross vehicle weight, with axle limits also in play. Your exact allowance depends on axle count, spacing, state rules, and permits.

A double drop can carry many oversized loads. However, you must match the trailer and axle setup to the job. Some setups handle loads well over standard limits once operators add axles and pull permits for heavier moves.

Common use cases for heavy equipment and oversized loads

A double drop trailer fits freight that checks one or more of these boxes:

- Tall equipment that risks height issues on step decks or standard drop decks

- Machines with high centers of gravity, where a lower ride improves stability

- Loads that need to be driven on loading through a removable gooseneck

- Odd shapes that sit better in the well than on a flat platform

- Freight that needs maximum height room without moving to extreme specialty solutions

If you move heavy equipment across mixed routes, a double drop deck trailer often gives you more flexibility than you expect. It helps you manage trips that involve highways, city streets, jobsite entrances, and rough access roads. You won’t have to worry about height at every bridge or sign.

This matters even more on jobs where the load height changes depending on how you position the boom, bucket, blade, or other attachments. By keeping the machine lower in the well, you gain extra height room and a steadier ride, which can make permits, routing, and safe loading decisions a lot easier.

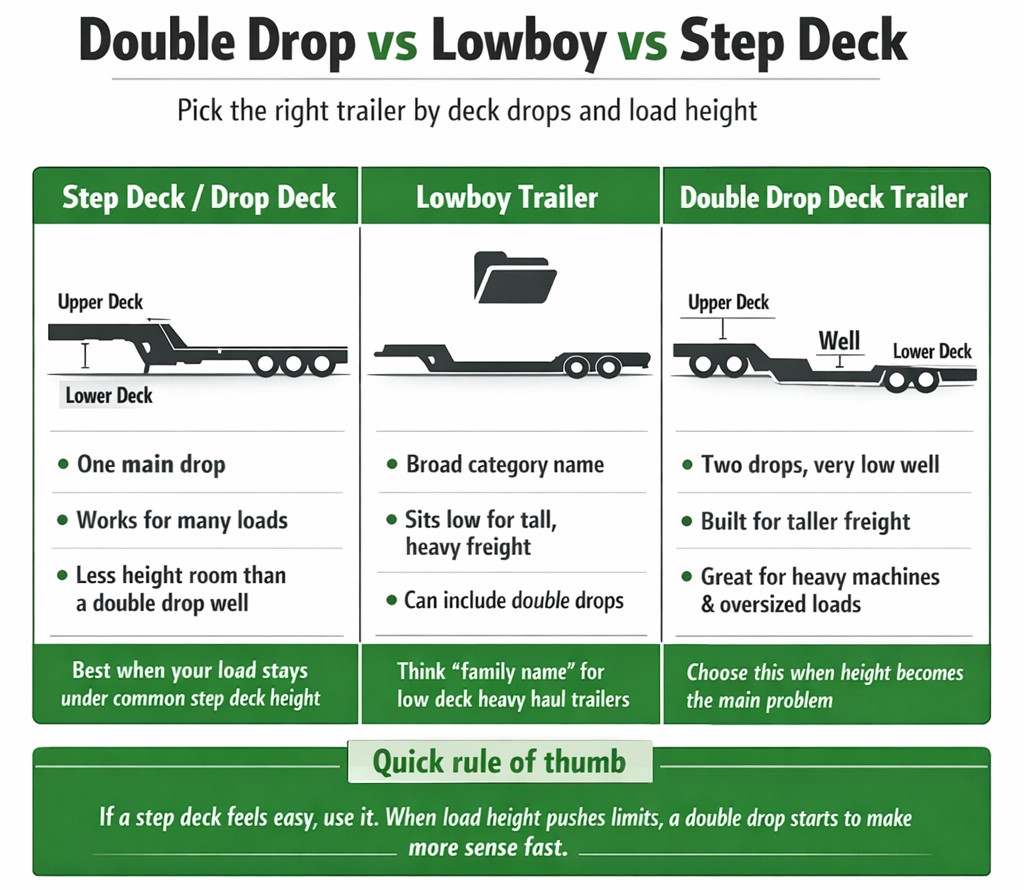

Double drop trailer vs lowboy trailer vs step deck

People often mix these terms, so here is a simple way to think about them:

Step deck and drop deck trailers: One main drop. They work well for many loads, but they run out of height sooner than a true double-drop well.

Lowboy trailer: A larger category. Many people treat double drops as lowboy-style since they sit low and target heavy, oversized freight.

Double drop deck trailer: A lowboy style with two drops and a very low well, built for taller freight and heavy machines.

If your load fits within common step-deck height planning numbers, a step deck may feel easier day to day. When the load crosses that line, the double drop starts to make more sense in a hurry.

Practical buying and dispatch checklist

Before you book a double drop trailer, run through these questions:

- What is the loaded height at the highest point?

Measure from the ground to the top of the load as it will ride on the well, not just the machine’s brochure height.

- How much ground clearance does your route require?

Low decks can scrape on sharp transitions.

- Do you need a removable gooseneck?

If you plan to drive on loading at job sites, an RGN setup saves time and equipment.

- What is the true weight, and where does it sit?

Heavy equipment often concentrates weight in a small footprint. Load position impacts axle weights.

- Do you need permits or escorts?

Oversize rules vary by state, and height is often the trigger for route restrictions.

Security tips that actually help

You already know the basics, so here are the points that bite people on double drops:

Mind the well transitions

The change from the upper deck to the well creates edges and angles. Your chains and binders need clean pull lines that do not rub against sharp corners.

Plan tie-down points early

Some machines limit where you can hook. Confirm you have enough anchor points on the trailer for the machine’s weight class.

Keep the load low and centered

A low deck helps stability, but off-center weight still causes sway, tire heat, and axle issues.

Final take

A double drop trailer earns its place when height becomes the problem you cannot negotiate with. The low well and smart features, like a removable gooseneck, make it a great choice. It is perfect for heavy equipment that needs a stable, low ride from pickup to delivery. It also works well for taller and oversized loads where every inch of deck height matters and a step deck or standard drop deck runs out of room fast.

Watch the deck height and ground clearance. This is important if your route has steep driveways, rough job sites, or tight entrances. These conditions can cause the trailer to bottom out. Always plan around weight limits like 80,000 lbs and axle rules, because weight distribution and axle spacing can change what you can haul and what permits you need.