Moving large machinery demands more than horsepower; it requires mastering heavy equipment securement. When you load bulldozers, excavators, or other heavy vehicles onto a trailer, every chain, strap, and anchor point plays a role. Use these proven techniques to meet cargo securement rules, DOT tie-down requirements, and load securement regulations while transporting machinery safely.

Why Proper Securement Matters

When you haul gear, you face risks if you ignore cargo securement rules set by the Federal Motor Carrier Safety Administration (FMCSA). The Federal Motor Carrier Safety standards and Motor Carrier Safety Administration guidance mandate proper securement for commercial motor vehicles. Failure to follow these rules can lead to load shifts, road hazards, or fines. You protect your crew, other drivers, and your cargo’s integrity by following every step.

Understand Regulations: FMCSA, DOT, and State Rules

Before you pick chains, verify how oversized load permits, route restrictions, and DOT tie-down requirements affect your move. FMCSA classifies loads based on size, shape, or weight so that each trailer run may demand different paperwork. Review your state’s permit process and load securement regulations to avoid surprises. Remember that some states require pilot cars when dimensions exceed limits, so plan boarding and inspection times accordingly.

Know Your Working Load Limit (WLL) and Accessory Equipment

Every chain, strap, and binder carries a Working Load Limit (WLL). Inspect each link and label before use. When you choose accessory equipment, like chain tensioners and load binders, match their WLL to your cargo’s weight.

Overloading a chain or strap voids its rating and creates a failure point in your securement system. Always use accessories rated for heavy loads and keep extra gear on hand for unexpected jobs.

Select the Right Securement Equipment and Securing Devices

Your securement equipment must match your cargo’s demands. You rely on:

- Chains and binders: Ideal for steel machinery and equipment with secure tie-down points.

- Heavy-duty straps: OSHA-approved webbing straps protect painted surfaces and sensitive parts.

- Winches and ratchet mechanisms: Provide consistent tension and quick release when you unload.

Each securing device must display its WLL and meet FMCSA standards. Keep backup straps and vehicle equipment—like edge protectors and corner guards—within reach. A complete securement system doesn’t leave anything to chance.

Anchor Points and Edge Protection

Choosing strong anchor points on both the trailer and the machine prevents slippage under stress. Inspect your trailer bed’s welds, lugs, and frame mounts before you hook up. On the equipment side, tie into the designated lift points that manufacturers recommend.

Always add edge protection, rubber or plastic guards, where chains or straps contact sharp metal corners. Edge protection prevents webbing cuts and chain wear, keeping cargo and straps intact.

Tie-Down Requirements for Heavy Equipment

FMCSA defines minimum tie-down requirements for heavy equipment based on cargo weight and trailer length. You must apply at least one tie-down for every 10 feet of cargo length, plus one extra tie-down.

For example, a 25-foot excavator needs three securement points. Place the first at the front, the next at the rear, and the third in the middle. Use tensioners to remove slack. A tight rig stays steady through every curve and bump.

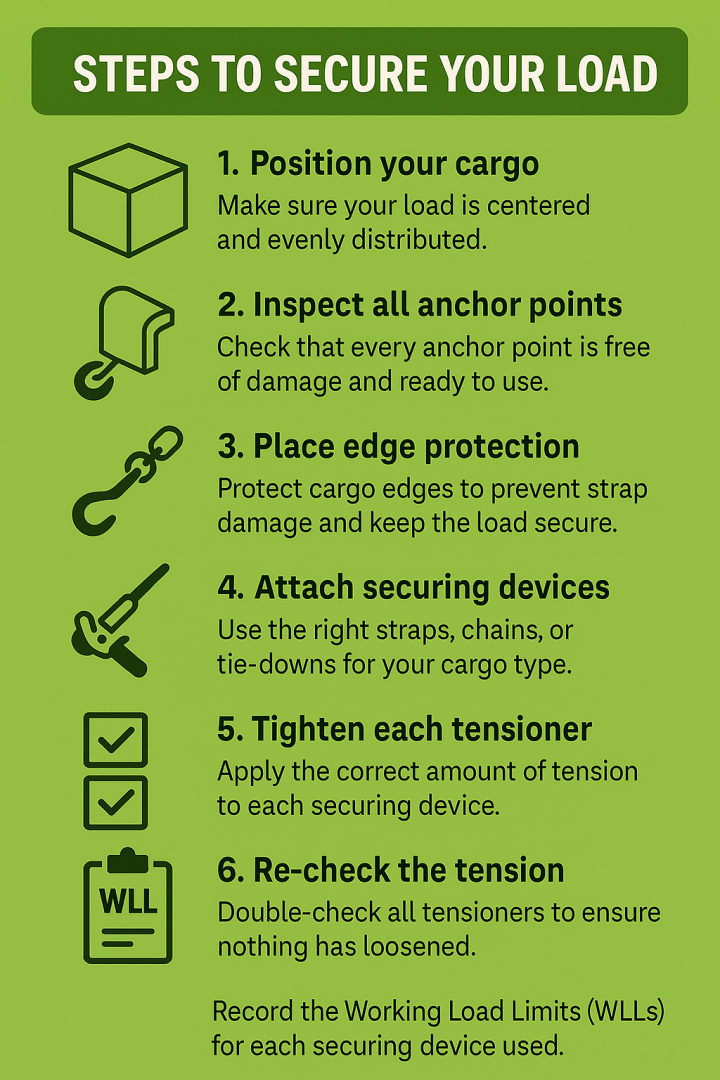

Steps to Secure Your Load

- Position your cargo on the trailer floor for balanced weight distribution.

- Inspect all anchor points, both on the trailer and the equipment.

- Place edge protection under every chain or strap.

- Attach securing devices—chains, straps, or binders—at the front.

- Tighten each tensioner until the load stops shifting by hand.

- Re-check the tension after a short test drive.

- Document WLLs and take photos to prove proper securement in case inspectors ask.

These steps help you meet cargo securement rules, satisfy load securement regulations, and protect your team.

Common Mistakes to Avoid

Some operators skip mandatory equipment checks or ignore the cargo’s size, shape, or weight when choosing tie-downs. Others fail to account for road vibrations that loosen straps.

Don’t let shortcuts compromise safety. After the first 50 miles, test tension and inspect straps. Replace frayed straps and bent chains immediately. Staying proactive prevents costly delays and accidents.

Advanced Tips for Veteran Drivers

When you handle high-value loads, layer your securement system. Combine chains for strength with straps for shock absorption. Use snag-proof winches to adjust tension on the fly.

Consider investing in smartphone-enabled load sensors that alert you if tension drops below safe levels. These sensors let you monitor your securement equipment in real time, even when you push through long hauls.

Transporting Heavy Equipment: Beyond the Basics

While you master onboard techniques, remember that proper documentation saves time at weigh stations. Record the serial numbers of heavy vehicles, equipment, and machinery, cargo dimensions, and WLL details in your log: share permit copies and route maps with dispatch. When everyone knows the plan, you speed through checkpoints without unexpected delays.

Wrap-Up

Safe transporting heavy equipment starts with knowing and applying every cargo securement rule. Use the right securement equipment, verify working load limit WLL ratings, and protect straps with edge protection. Anchor your load at factory-approved points, follow tie-down requirements for heavy equipment, and document every step.

When you follow load securement rules and safety standards, you reduce risks. This also helps you work more efficiently. Additionally, it protects your reputation while driving.