If you have ever been in a truck yard or seen a convoy on the highway, you are not alone. You may have wondered why there are so many types of trailers. From flatbeds to reefers, lowboys to tankers, manufacturers design each trailer type for a specific job.

Choosing the right trailer isn’t just about hooking up to a rig and hitting the road. It’s about matching your freight to the right trailer type. When you choose the right one, you get better safety, fewer delays, and improved results.

In this guide, we’ll break down the most common trailer types, explain how they work, and help you figure out which one is right for your job.

Why Trailer Type Matters

Every load is different. A trailer that works great for steel beams won’t be the best choice for frozen food or heavy machinery. And if your freight doesn’t fit the trailer’s specs—like its height, width, or weight—you could face road fines or even damage your cargo.

Choosing the wrong trailer can lead to:

- Delays at pickup or delivery

- Unsafe driving conditions

- Extra costs for permits or escorts

- Damage to your truck or load

Choosing the right trailer means:

- Easy loading and unloading

- Better fuel efficiency

- Safer driving

- Fewer headaches on the road

Let’s break down the major trailer types you’re likely to encounter.

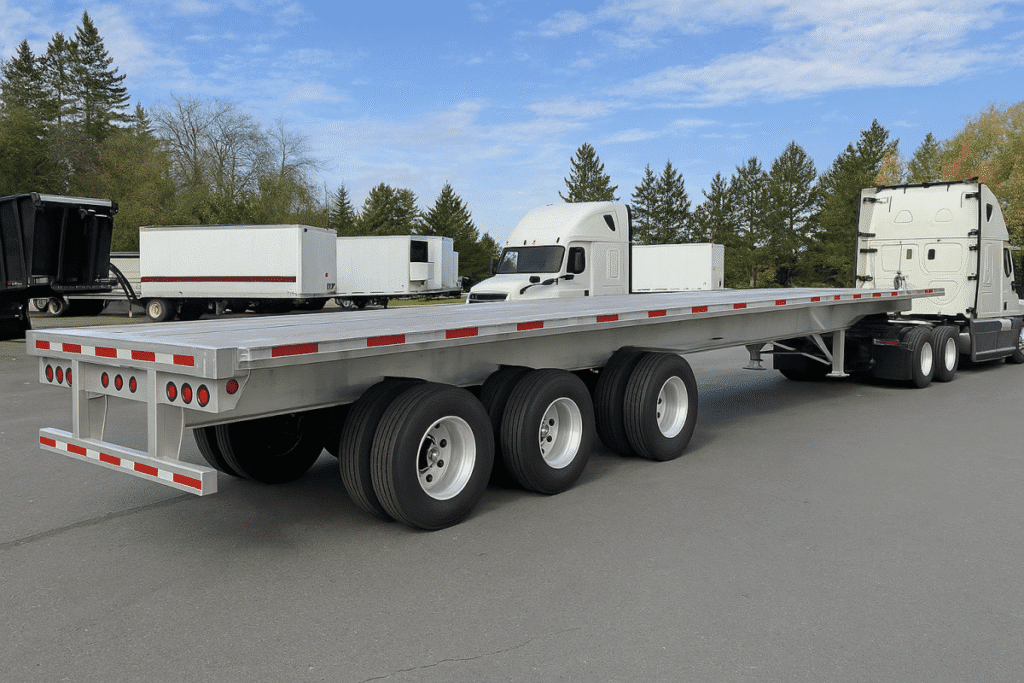

1. Flatbed Trailers

Flatbed trailers are some of the most versatile trailers on the road. A flatbed trailer is a completely open trailer with no walls or roof—basically a flat surface on wheels. This makes it super easy to load cargo from the sides, back, or even from above using a crane or forklift.

As they don’t have walls or a roof, which makes them perfect for hauling materials that are oversized or oddly shaped.

Best for:

- Construction materials (like lumber or steel beams)

- Steel beams

- Farm equipment

- Machinery

- Other oversized loads that don’t need full enclosure

Pros:

- Easy loading and unloading from any side

- Great for large equipment

- Flexible for different cargo shapes

- Ideal for jobs without docks

Cons:

- No protection from weather

- Requires tarping for sensitive cargo

- Needs proper securement to avoid cargo shift

Flatbed trailers usually come in lengths of 48 or 53 feet long, and they’re rated for up to 48,000 lbs of cargo.

2. Step Deck Trailers (AKA Drop Deck Trailers)

Also called a drop deck trailer, a step deck trailer has two levels: an upper deck and a lower deck. This design allows you to haul taller loads while staying within legal height limits.

Best for:

- Tall equipment and machinery

- Large machinery

- Farm equipment

- Forklift-access loads

Pros:

- More vertical space and height clearance

- Easy to load with forklifts or ramps

- Great for heavy equipment

- Great for legal compliance

Cons:

- Slightly more complex to load

- Not ideal for small, packaged goods

Step deck trailers are typically 48 to 53 feet long and allow cargo up to 10 feet high on the lower deck.

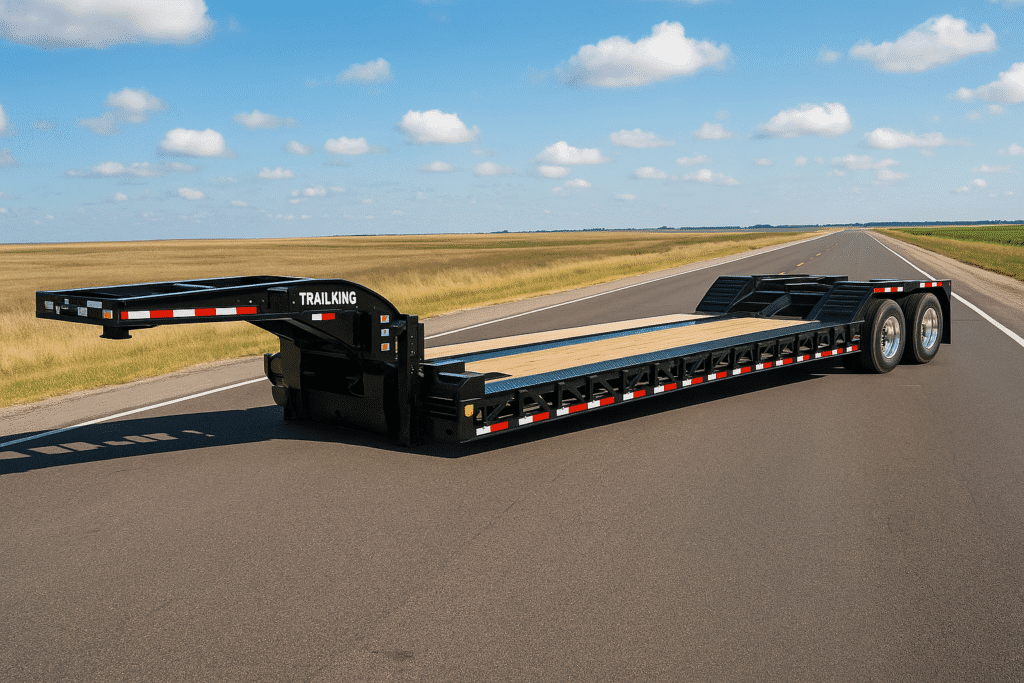

3. Lowboy Trailers

A lowboy sits exceptionally close to the ground, even lower than a step deck. People use it for hauling extremely tall or heavy cargo, especially construction equipment.

Best for:

- Heavy equipment (bulldozers, cranes, etc.)

- Large construction machinery

- Over-height freight

Pros:

- Great for extreme height clearance

- Excellent for heavy-duty work

Cons:

- Requires special loading equipment

- May need permits for extreme loads

Lowboys are specifically designed for jobs where size and weight are beyond normal limits.

4. Enclosed Trailers

Enclosed trailers are fully covered trailers with walls and a roof. They protect the cargo from weather and theft, making them perfect for delicate or high-value items.

Best for:

- Electronics

- Furniture

- Clothing

Pros:

- Full protection from rain, wind, and theft

- Great for box cargo

- Easy to secure items inside

Cons:

- Only rear loading

- Not for oversized freight

- Can’t haul oversized or oddly shaped cargo

These trailers are used to haul all sorts of packaged goods across the country and are a staple in retail logistics.

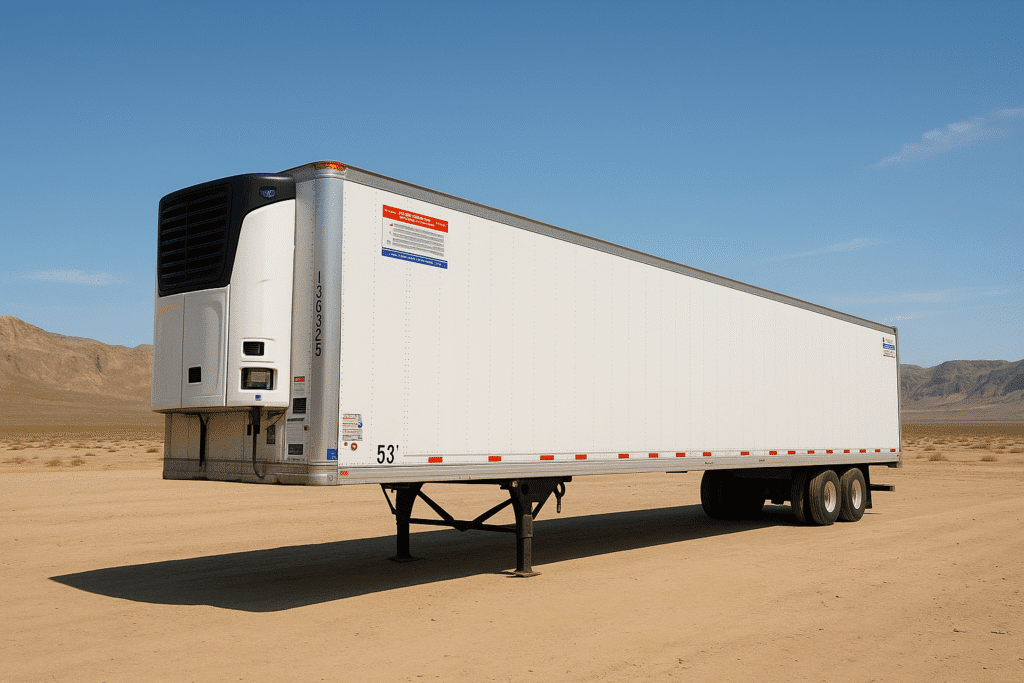

5. Refrigerated Trailers (Reefers)

Refrigerated trailers are just like enclosed trailers, but with built-in cooling units. They keep your cargo at a set temperature.

Best for:

- Food and beverages

- Medicine

- Perishable goods

- Anything that’s temperature-sensitive

Pros:

- Keeps loads fresh or frozen

- Controlled temperature

- Ideal for long-distance shipping of perishables

Cons:

- Heavier because of cooling system

- More expensive to maintain

Reefers are essential in grocery and pharmaceutical supply chains.

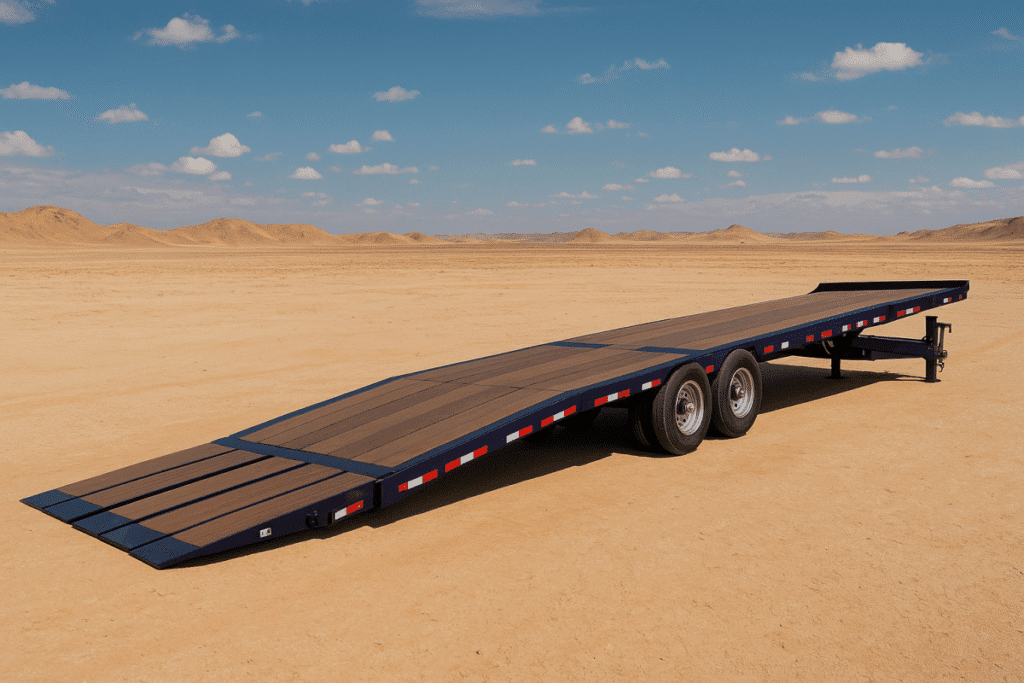

6. Gooseneck Trailers

Gooseneck trailers connect to a ball hitch in the bed of a pickup truck, rather than to the bumper. This gives the trailer more stability and allows it to carry heavier loads.

Best for:

- Farm equipment

- Hay bales

- Small construction equipment

Pros:

- Stable and strong connection

- Higher weight capacity

Cons:

- Requires a pickup with a gooseneck hitch

- Not for standard commercial rigs

Gooseneck trailers are used a lot in agriculture and rural industries.

7. Utility Trailers

Utility trailers are small, open trailers often pulled by a pickup truck or SUV. They’re used for light-duty jobs and personal hauling.

Best for:

- Lawn mowers

- ATVs

- Moving furniture

Pros:

- Affordable

- Easy to maneuver

Cons:

- Limited capacity

- No protection from weather

Utility trailers are great for short hauls and everyday use.

8. Dump Trailers

Dump trailers are trailers with hydraulic lifts that allow you to tip the bed and dump the cargo.

Best for:

- Gravel

- Sand

- Construction materials

Pros:

- Self-unloading

- Strong and durable

Cons:

- Not suited for palletized goods

Dump trailers are essential on job sites where unloading speed matters.

9. Equipment Trailers

Equipment trailers are flat or tilt-deck trailers built for hauling materials and large equipment like bobcats, scissor lifts, or tractors.

Best for:

- Construction and landscaping machinery

- Farm equipment

Pros:

- Strong decks

- Ramps for loading

Cons:

- Not enclosed

- Must secure loads properly

These trailers are used to haul heavy tools and machines to and from job sites.

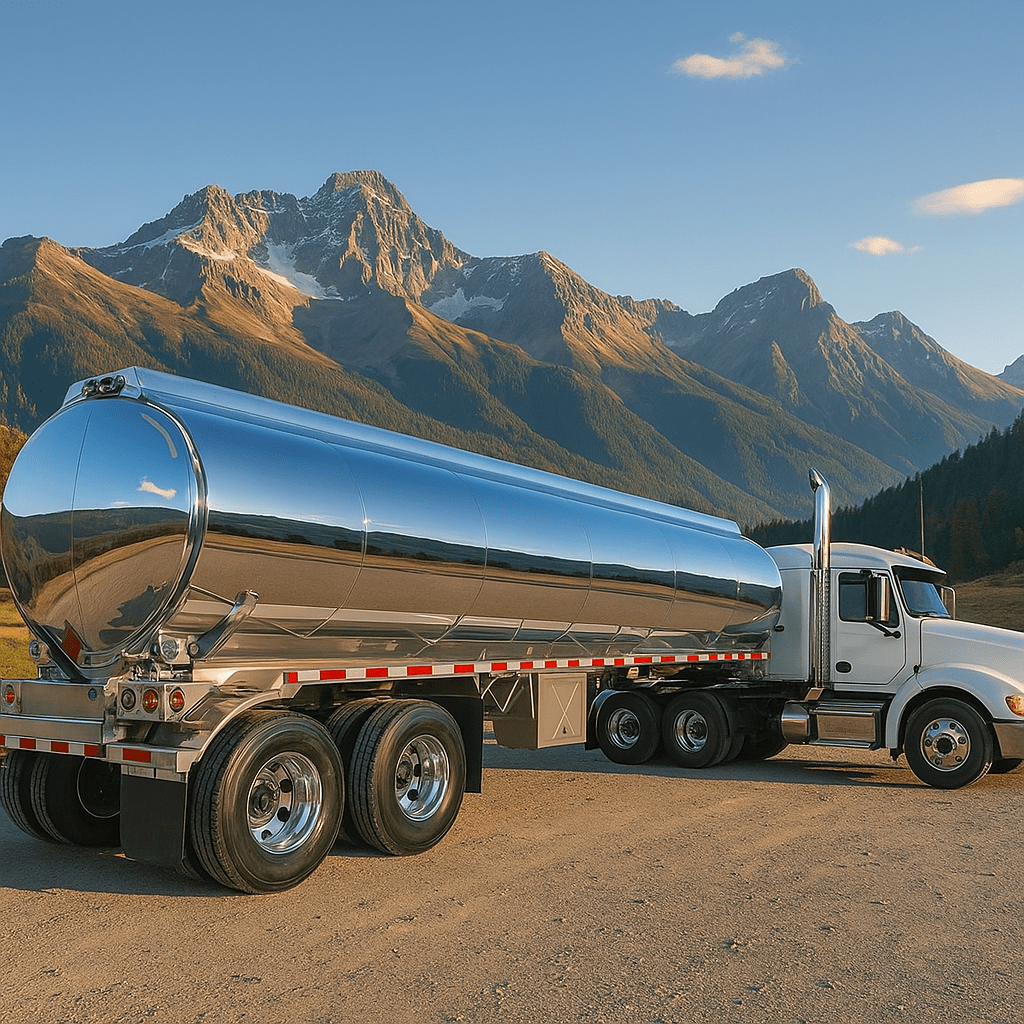

10. Tanker Trailers

Tanker trailers are made to carry liquids like fuel, milk, or chemicals. They’re shaped like a long cylinder and often have safety features built-in.

Best for:

- Gasoline

- Water

- Liquid chemicals

Pros:

- Safe for transporting liquids

- Comes in food-grade or hazmat styles

Cons:

- Requires special training to operate

- Not versatile for other load types

- Can be dangerous if misused

11. Conestoga Trailer

This is a flatbed with a soft, sliding tarp system. The tarp protects your load like a dry van would but rolls back for easy side or top loading.

Best For

- Freight that needs weather protection but is too large for a van

- Machinery and metal parts

Pros

- Combines weather protection with easy loading

- No need for tarps and straps

Cons

- More moving parts = more potential maintenance

- Slightly less space due to the tarp frame

12. Extendable Flatbed Trailer (Stretch Trailer)

These trailers look like normal flatbeds but can stretch out to carry extra-long loads like pipes or beams. When not stretched, they’re compact.

Best For

- Wind turbine blades

- Structural steel

- Bridge components

Pros

- Adjustable length

- Handles freight that wouldn’t fit on a regular trailer

Cons

- Often requires permits

- Needs more attention during loading

13. Double Drop Trailer

This trailer has a low center section (the “well”) and raised front and rear decks. It’s great for super-tall freight that would never fit on a standard trailer.

Best For

- Oversized industrial equipment

- Very tall loads that need to sit low

Pros

- Great for extreme height clearance

- Strong frame for heavy machinery

Cons

- Not versatile for general freight

- More difficult to load and unload

14. Side Kit Trailer

This is a flatbed trailer with removable sides and a tarp over the top. It gives some protection without the full enclosure of a dry van.

Best For

- Gravel, sand, and mulch

- Steel coils or bundled materials

Pros

- Protects cargo from wind and weather

- Easy to load from sides

Cons

- Not as secure as a dry van

- More effort to tarp and untarp

15. Removable Gooseneck (RGN) Trailer

RGN trailers have a detachable front, which lets heavy machinery be driven onto the trailer from the front. They also have a super-low deck.

Best For

- Construction equipment like excavators and bulldozers

- Military or mining vehicles

Pros

- Great for drive-on equipment

- Can handle very heavy and tall loads

Cons

- More expensive to operate

- Often needs permits

How to Choose the Right Trailer Type

Now that you know the main trailer types, how do you pick the one you actually need? Ask yourself a few questions:

What am I hauling?

- Is cargo tall, wide, or oddly shaped?

- Does it need to stay cold or dry?

How heavy is the cargo?

- Check weight limits and axle counts.

How will they load it?

- Forklift, crane, or drive-on?

How far is it going?

- Some trailers work better for long hauls than short, local trips.

Are permits required?

- Oversized loads need planning ahead.

Here’s a quick snapshot of how different industries use these trailers:

| Industry | Common Trailer Types |

| Construction | Flatbed, Step Deck, Lowboy, RGN |

| Agriculture | Flatbed, Gooseneck, Side Kit |

| Retail / Distribution | Dry Van, Reefer |

| Energy & Utilities | Extendable, Double Drop, Tanker |

| Food & Beverage | Reefer, Dry Van |

| Manufacturing | Conestoga, Flatbed, Dry Van |

Final Thoughts: Different Trailer Types for Different Jobs

Whether you’re hauling food, machines, or boxes, there’s a trailer designed to help. From flatbed trailers and step deck trailers to lowboy trailers and refrigerated trailers, each trailer solves a different problem. Some are better for easy loading and unloading. Others carry heavy equipment or keep your goods safe from the weather.

There’s no one-size-fits-all when it comes to trailers. The right trailer depends on your cargo, your route, and how often you haul.

If you’re hauling tall freight, a step deck or lowboy is the way to go. If you’re moving general goods and want weather protection, a dry van works well. For liquids, a tanker is the only safe choice. And if you need flexibility, consider flatbeds or Conestoga trailers.

No matter what you haul, knowing about trailer types will help you make better choices. This knowledge can help you avoid costly mistakes and keep your freight and your truck on the road.

At the end of the day, the best trailer is the one that fits your cargo, your route, and your equipment. If you’re not sure which one to pick, reach out to our team at Interstate365.com. We’re happy to help you find the right fit.

Choosing the right trailer doesn’t have to be hard. With a little planning and the right info, you can match your freight to the perfect trailer—and get the job done right the first time.