Selecting among the types of heavy haul trailers is a strategic decision. The right platform aligns deck geometry, axle configuration, and load path with your cargo and route constraints. Get those variables right, cut risk, compress loading time, and protect margins on every move.

A quick framework for trailer selection

When considering types of heavy haul trailers, start with the four fundamentals: height, width, weight, and loading method. Then, layer in route controls like bridge clearances, axle limits, and turning radius. Finally, confirm securement points and the center of gravity. This sequence helps you narrow the field from all haul trailer types to the single type of trailer that fits your mission.

Flatbed trailer: speed, access, and broad utility

A standard flatbed trailer excels when moving legal-height freight and needs fast side access. Crews load and unload with forklifts or cranes from any angle, saving time at multi-stop jobs and mixed freight runs.

Use a flatbed for construction materials, bundled steel, palletized goods, and crated industrial machinery. Proper weight distribution achieves stable handling and efficient tie-down geometry. Browse current options here: Flatbed Trailer.

Where flatbeds shine

- Legal-height freight with frequent stops

- Side loading at crowded docks

- Mixed commodities and swap-outs during route changes

What to verify

- Concentrated load rating for point loads

- Outrigger and stake pocket layout for unconventional shapes

- Dunnage plan to protect finishes and edges

Step deck trailer and drop deck trailer: clearance and stability

A step deck trailer lowers the main deck behind a short upper deck. That geometry increases vertical clearance without special permits in many states and provinces. It also lowers the center of gravity, which improves stability with tall machines. Add beavertail ramps and easy loading and unloading for wheeled heavy equipment.

You will also hear drop deck trailers used interchangeably with step deck trailers. Both deliver the same essential advantages for oversized loads that exceed legal height on a flatbed. See current models here: Step Deck Trailer.

Ideal step deck use cases

- Tall skids of industrial equipment

- Tractors, loaders, and compact dozers

- Mixed freight that needs a lower main deck and a top deck for lighter items

Key specifications to weigh

- Main deck height and length

- Ramp design and rated approach angle

- Axle spacing for bridge formula compliance

Lowboy trailers and double drop trailers: ultra-low for extreme height

When height rises beyond step deck limits, lowboy trailers and double-drop trailers take over. These heavy-duty platforms include a central well that sits very close to the pavement. That well carries tall excavators, transformers, generators, presses, and similar large loads. The low running height often removes complex reroutes around bridges and lines.

Many lowboys use a removable gooseneck trailer front. Operators drive machines on and off without forklifts or cranes. That feature cuts cycle time at job sites with limited infrastructure.

Why lowboy geometry matters

- Lowest practical deck height for extreme clearance

- Better lateral stability with massive topside mass

- Flexible securement points for irregular frames

Pre-trip checks

- Kingpin to rear-axle distance for local limits

- Axle group ratings and spread configurations

- Approach and breakover angles at site entrances

Gooseneck trailer dynamics and weight distribution

A gooseneck trailer couples over the truck frame near the axle centerline. That placement improves weight distribution and enhances control on uneven surfaces. Agriculture, energy, and construction teams favor goosenecks for tight sites and unpaved approaches.

A good gooseneck setup can improve handling. It does this without needing to over-specify axle groups. This is important when working on rough ground with heavy-duty loads.

Loading strategy and securement that protect profit

Plan loading with the same rigor you apply to routing. Place the densest mass over the drive axles and spread the remainder to maintain balanced weight distribution across groups. Keep the center of gravity low and forward of the rear pivot.

Use rated chains, binders, straps, corner protectors, and softeners that preserve finishes. Confirm tire pressures before departure. Re-scale after your first leg when practical. Good securement and scaling prevent heat buildup, blowouts, and suspension stress that shorten component life.

Spec choices that move the needle

You improve performance and reduce total cost when you specify the trailer to your operation’s dominant constraint.

- Deck architecture: Choose flatbed for speed and flexibility. Choose step deck trailer for height and stability. Choose lowboy trailers or double drop for extreme height and concentrated loads.

- Axle groups: Align tri-axle or quad options with state weight tables and typical payloads.

- Ramps and hydraulics: For wheeled machines, ramps reduce dock dependence and accelerate turns.

- Suspension and tires: Air-ride helps with sensitive machinery. High-quality tires mitigate heat during heavy cycles and long grades.

- Winches and chain wells: Place them where your crew can reach them without awkward angles.

- Lighting and visibility: Good lighting supports night staging and reduces ground time.

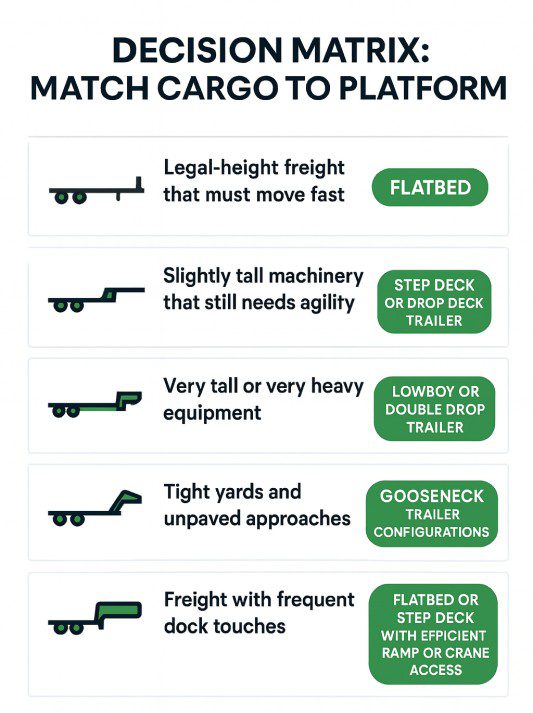

Decision matrix: match cargo to platform

Use this short matrix to connect freight profiles with the right platform among the types of heavy haul trailers.

- Legal-height freight that must move fast: flatbed

- Slightly tall machinery that still needs agility: step deck or drop deck trailer

- Very tall or very heavy equipment: lowboy or double drop trailer

- Tight yards and unpaved approaches: gooseneck trailer configurations

- Freight with frequent dock touches: flatbed or step deck with efficient ramp or crane access

Practical examples from the field

- Heavy equipment like excavators and pavers rides best in a lowboy well. You gain clearance and stability and shorten the site’s loading cycles.

- Construction materials such as I-beams, rebar, and lumber favor a flatbed trailer. Forklifts load and unload from both sides, which shrinks dwell time.

- Industrial machinery that runs just over legal height fits a step deck trailer. The lower main deck keeps the profile compliant while preserving handling.

Where to go next

If you want a broader overview of heavy hauling trailers, start here: Trailer Types Explained: Choosing the Right One. Then compare current flatbed trailer options on our Flatbed Trailer page. If your profile points to a lower deck solution, review our Step Deck Trailer inventory. You will also find drop deck trailer configurations on the same page.

Types of heavy haul trailers: Final take

Treat trailer selection as an engineering choice, not a habit. Quantify the cargo. Map the route. Define the loading method.

Match those facts to the platform geometry that solves the hardest constraint. You move safely when you match design, securement, and weight distribution with your load profile. You also load faster and protect profits on every mile.